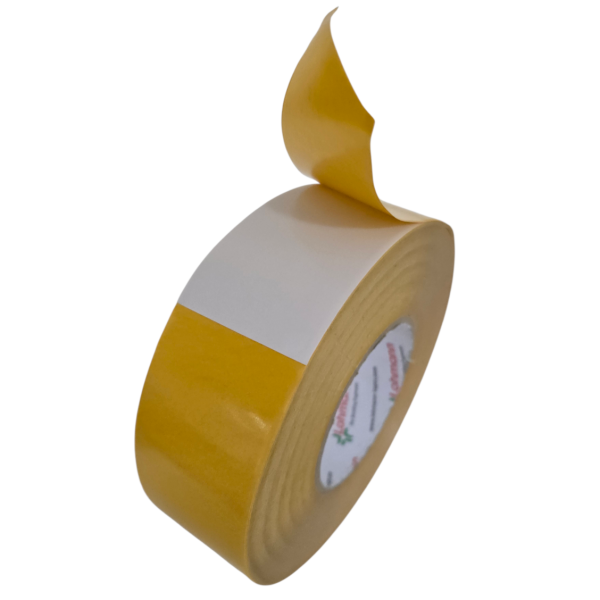

DuploCOLL® 370 mounting tape, double-sided adhesive tape, very strong adhesive

Colour: white

Double-sided adhesive tape with PVC backing and modified acrylate adhesive

Main applications:

- Self-adhesive finishing of extruded plastic and cladding profiles for permanent final assembly in the furniture industry

- Assembly of decorative parts and glazing bars, fastening of covers, holders and cable ducts

- Assembly of interior and exterior car mirrors in plastic housings Doubling

Properties:

- Good initial adhesion (tack)

- High shear strength

- Excellent ageing, weather and UV resistance

- Extensive resistance to the influence of chemicals (cleaners, petrol, oil)

- Ideal surface adaptation, even on rough substrates such as chipboard

- Thickness: 0.23 mm

- Liner: yellow silicone paper (havana)

- Adhesive: modified acrylate

- Backing: white PVC film

Technical data:

- Shear strength on stainless steel at +23°C (+/-2°C): 60 N / 625 mm²

- Peel strength 180° on stainless steel at +23°C (+/-2°C): 37 N / 25 mm

- Temperature range: -40°C to +80°C

- Peel strength after 24 hours at room temperature on various substrates:

- Soft PVC: 26 N/25 mm

- Polypropylene: 26 N/25 mm

- Polyethylene: 20 N/25 mm

- PTFE: 6 N/25 mm

- Hard PVC: 42 N/25 mm

- Glass: 44 N/25 mm

- Steel: 45 N/25 mm

- ABS: 34 N/25 mm

- Ascending heat test at 1 kg load, starting at 30 °C, temperature increase every 30 minutes by 10 °C: 100 °C

Processing and storage information

Surface condition

The surfaces must be dry, free of dust, oil, oxides, release agents and other contaminants.

Surface cleaning

The following cleaning agents, for example, can be used to remove dust, oil, release agents and other impurities:

Isopropanol/water 50/50

Heptane or ethanol

Acetone or MEK

Suitable other cleaning agents that do not leave any residues and do not attack the substrate.

Temperature

The most favourable processing temperature (object and ambient temperature) is between +15°C and +25°C.

Pressure

The strength of the bond is directly dependent on the contact that the adhesive has with the surfaces to be bonded. A short, high pressure (e.g. with a squeegee, pressure roller or pressure device, etc.) ensures good surface contact. The type and amount of pressure depends on the material (thin- or thick-walled, etc.) and the geometry of the components. Rule of thumb: approx. 20 N/cm².

Storage

The rolls should be stored in their packaging protected from light at a temperature between +15°C and +25°C and a relative humidity of 50%.

Note

The technical information is given to the best of our knowledge, but is not binding. The information only has the character of a general recommendation. The suitability of the product for the desired purpose must be ensured by own tests under the original conditions. A legal assurance of certain properties cannot be derived from our information.